It operates by creating a Vacuum Leak Tester in a chamber housing the test sample and monitoring the vacuum level for any signs of decay, which would indicate the presence of a leak. This tool is essential for ensuring that products are packaged in airtight conditions, which is crucial for maintaining product quality, safety, and longevity.

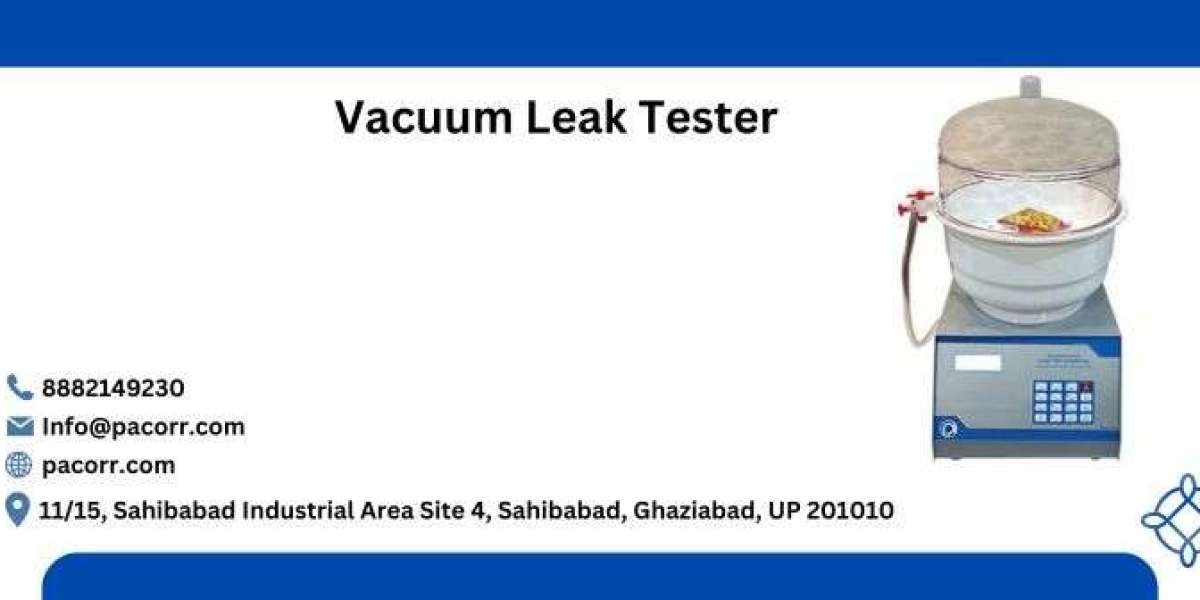

What is a Vacuum Leak Tester?

A Vacuum Leak Tester is a device that checks for leaks in sealed packages or systems by creating a vacuum environment. The principle is straightforward: if a package or system is leak-proof, it will maintain a specified vacuum level for a certain period. Any drop in vacuum indicates a leak. This method is non-destructive, making it an ideal choice for testing product packaging without damaging the contents.

What Vacuum Leak Testers Work

The process typically involves:

Placement: The item to be tested is placed within the chamber of the tester.

Vacuum Creation: The machine extracts air from the chamber to form a vacuum.

Monitoring Phase: The vacuum level is monitored over a predetermined period; any decrease in pressure indicates a potential leak.

Analysis and Reporting: The tester provides results that will indicate either the integrity of the seal or the presence of a leak.

Choosing the Right Vacuum Leak Tester

When selecting a Vacuum Leak Tester, consider the following factors:

Leak Detection Sensitivity: Choose a tester that can detect the smallest leaks required by your industry standards.

Size and Portability: Depending on your operational needs, you might prefer a compact and portable model over a larger, stationary one.

Custom Features: Look for features that can be tailored to your specific testing requirements, such as adjustable vacuum levels and test durations.

Applications of Vacuum Leak Testers

Food Industry: To ensure the longevity and safety of packaged foods by checking for air leaks that could lead to spoilage.

Pharmaceuticals: To maintain the sterility and effectiveness of packaged medical products.

Automotive: To test components such as brake systems and fuel injectors for air leaks that could impair functionality.

Electronics: To verify that enclosures are secure against environmental contaminants that could damage components.

Key Features of Vacuum Leak Testers

Sensitivity and Accuracy: High sensitivity to detect even the smallest leaks, ensuring product safety and quality.

Versatility: Suitable for a wide range of products, from food packaging to automotive components.

User-Friendly Interface: Easy-to-operate controls and digital displays that provide immediate feedback.

Durability: Built to withstand industrial environments, ensuring longevity and reliability.

Customization: Options to customize settings according to specific testing requirements.

Benefits

Quality Assurance: Helps maintain high standards of quality control, ensuring products meet regulatory compliance and customer expectations.

Cost Efficiency: Prevents costly recalls and waste by catching faults before products reach the market.

Enhanced Reputation: Builds consumer trust by consistently delivering products that are safe and reliable.

Product Range

Pacorr offers a diverse array of testing instruments, including:

Vacuum Leak Testers: Ideal for ensuring the integrity of packaging in food, pharmaceuticals, and consumer goods.

Compression Testers: Used to determine the compressive strength of materials like cardboard, metal, and plastics.

Tensile Strength Testers: Measures the force required to pull materials apart, essential for assessing product durability and quality.

Environmental Test Chambers: Simulates different environmental conditions to test products’ resistance to humidity, temperature, and other climatic factors.

Frequently Asked Questions (FAQ)

What is the accuracy of a Vacuum Leak Tester?

Vacuum Leak Testers are highly accurate, capable of detecting very small leaks that might not be visible through other means.

Can it test all types of materials?

While ideal for many types of materials, certain ultra-flexible materials may require different testing methods or specialized adapters.

How long does a typical test take?

Most tests can be completed in a few minutes, depending on the vacuum level required and the product's characteristics.

What maintenance is required for a Vacuum Leak Tester?

Regular calibration and occasional servicing are recommended to maintain accuracy and functionality.

Where can I purchase a Vacuum Leak Tester?

For a comprehensive range of Vacuum Leak Testers tailored to various industrial needs, visit Pacorr.com.

Conclusion

The Vacuum Leak Tester is an indispensable tool for manufacturers and quality assurance professionals who demand the highest standards of safety and quality. With its ability to detect even the smallest leaks, it is a critical component of any quality control system. To explore more about how Pacorr’s Vacuum Leak Testers can benefit your operations,

For further information or to see the Vacuum Leak Tester in action, visit pacorr.com.